Raw Material

We source and supply all types of Raw Material for the steel industry.

Steel is produced from iron ore, a natural compound containing iron, oxygen, and other minerals. The raw materials for steelmaking are extracted and then converted into steel through two primary methods: the blast furnace/basic oxygen furnace route and the electric arc furnace route which uses scrap, pig iron and HBI. Both methods are continually being refined to address the challenge of low-emission steel production.

Main Trading Categories

Iron Ore

Iron ore is a naturally occurring mineral from which iron is extracted for use in steel production. It primarily consists of iron oxides, such as hematite (Fe₂O₃) and magnetite (Fe₃O₄), which are mined from the earth. After mining, the ore is crushed, screened, and processed to increase the iron concentration, often through methods like beneficiation. The concentrated iron ore is then used in blast furnaces or direct reduction processes to produce pig iron or direct reduced iron (DRI), which are essential raw materials in steelmaking. Iron ore is a critical component of the global steel industry, driving infrastructure development and economic growth.

Pig Iron

Pig iron is a basic form of iron produced as an intermediate step in the steelmaking process. It is created by smelting iron ore in a blast furnace along with coke (a carbon-rich material) and limestone. The resulting molten iron, known as pig iron, contains a high carbon content (typically 3.5-4.5%).

In steelmaking, pig iron is typically refined through processes such as basic oxygen steelmaking or electric arc furnace methods to reduce its carbon content and remove impurities, converting it into steel. This refined steel is then used to produce a wide range of products across various industries.

HBI

Hot briquetted iron (HBI) is a compacted form of direct reduced iron (DRI), produced by compressing DRI at high temperatures to form dense, pillow-shaped briquettes. This process helps reduce the reactivity and the risk of spontaneous combustion, making HBI safer and easier to transport and store compared to DRI.

HBI is primarily used in electric arc furnace (EAF) steelmaking as a substitute for scrap metal, providing a consistent and high-quality feedstock that enhances the quality of the steel produced. Its dense form also allows for efficient handling and shipping, making it a valuable raw material in the steel industry.

Steel Scrap

HMS (Heavy Melting Steel) and shredded scrap are two key types of recyclable steel used in the steelmaking industry.

HMS and shredded scrap are essential in the recycling process, providing the raw materials needed for sustainable steel production. Both grades are used in electric arc furnaces (EAFs) to produce new steel, contributing to the recycling and sustainability of the steel industry. Shredded Scrap is processed steel scrap that has been mechanically shredded into smaller, uniform pieces, typically around the size of a fist. It is more uniform and cleaner than HMS scrap, making it easier to handle, transport, and melt in furnaces.

Main Trading Categories

Steel HMS Scrap

HMS refers to heavy melting steel scrap, categorized primarily into HMS 1 and HMS 2 based on thickness and composition.

HMS 1 (80%)

This is heavy melting scrap consisting of iron and steel, usually free from major impurities. It includes larger and thicker steel items like plates, beams, and rebar, which are no less than 1/4 inch (6.35 mm) in thickness.

HMS 2 (20%)

This consists of thinner steel scrap, such as lighter gauge steel that is less than 1/4 inch thick. It includes items like smaller pipes, strips, and other thin materials.

Steel Shredded Scrap

Preferred for its consistency and quality, shredded scrap is widely used in steel mills to produce high-quality steel products, ensuring efficient melting and minimal impurities.

Steel 210/211 shredded scrap refers to a specific grade of recycled steel material used in steelmaking. This type of scrap is produced by shredding various steel items into small, uniform pieces.

Shredded scrap generally contains fewer contaminants than other scrap types, resulting in cleaner steel output with minimal impurities. It is highly valued by steel mills, particularly in electric arc furnaces (EAFs), where it can be quickly melted down and recycled into new steel products.

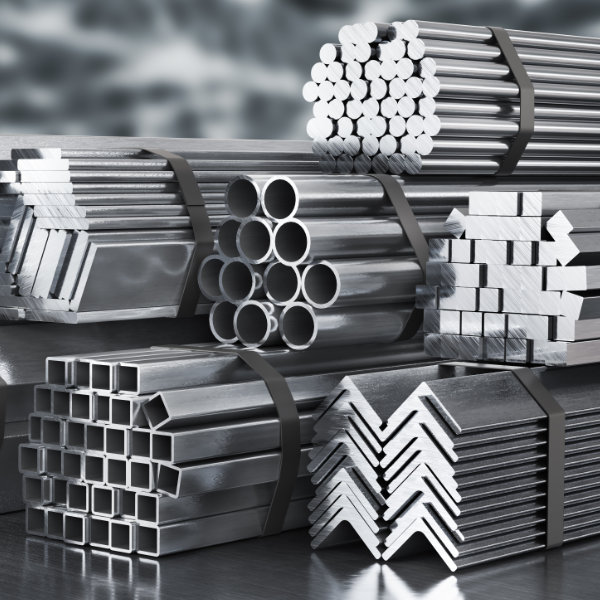

Semi Finished

We specialise in trading various types of Semi Finished products.

Semi-finished steel products, commonly known as 'semis' in the steel industry, are intermediate products created through continuous casting in modern steel facilities. These semis are further processed to become finished products. There are three main categories of semi-finished steel products that we trade:

Main Trading Categories

Steel Billets

Steel billets are semi-finished products made by casting molten steel into a specific shape, typically rectangular or square. They serve as raw materials for further processing in rolling mills to create various steel products such as debars, wire rod and steel bars. Steel billets are valued for their uniform composition, high strength, and versatility, making them essential in construction, manufacturing, and metalworking industries. They are produced in different sizes 60x60mm to 160x160mm and grades, depending on the specific application requirements.

Steel Slabs

Steel slabs are semi-finished products that are flat, rectangular pieces of steel created by casting molten steel. These slabs are typically produced in steel mills from thickness of 180mm to 300mm with widths between 950mm to 2500mm. They are used as the starting material for rolling into flat products like reversing mill plates, sheet and hot rolled coils. Steel slabs are integral in various industries, including construction, automotive, and shipbuilding, due to their strength, durability, and ability to be further processed into a wide range of steel products.

Long Products

With our global network we deal with the procurement and supply of Long Steel products.

Long steel products, primarily made from billets and blooms through EAF and BOF furnaces, are widely used in construction.

Main Trading Categories

Steel Reinforcing Bars

Hot-rolled with deformation patterns, sometimes thermo-mechanically treated (TMT) for extra strength, used to reinforce concrete in construction.

Steel reinforcing bars, commonly known as rebar, are steel rods used to strengthen concrete structures. In straight lengths, these bars are typically smooth or deformed (with ridges) to improve their bond with concrete. Rebar in straight lengths is available in various diameters, usually ranging from 6mm to 40mm, and is commonly cut to standard lengths like 12 meters. These bars enhance the tensile strength of concrete, which is inherently strong in compression but weak in tension, ensuring structural integrity in construction projects such as buildings, bridges, and roads.

Steel Reinforcing Coils

Reinforcing steel coil, also known as rebar coil, is a type of steel product used primarily in the construction industry to reinforce concrete structures.

It is produced as long steel rods that are coiled into rolls, making it easier to transport and handle on construction sites. The coiled form allows for flexibility in length and the ability to cut to specific sizes as needed.

Typically made from carbon steel, reinforcing steel coil is designed to have high tensile strength and is often ribbed or deformed to provide better grip with concrete, enhancing the bond between the steel and the concrete.

It is widely used in the reinforcement of concrete in structures like buildings, bridges, and roads.

Steel Wire Rods

Small diameter, hot-rolled coils, some cold-drawn, used in applications like fences, fasteners, and hardware tools.

Steel wire rod is a semi-finished product, typically in the form of coiled wire, used as a raw material for manufacturing various wire products. It is made from hot-rolled steel and has a round cross-section, with diameters typically ranging from 5.5mm to 14mm. Steel wire rods are commonly used in the production of wire for construction, automotive parts, fasteners, and welding electrodes, as well as in the creation of wire mesh, fencing, and springs. The wire rod is valued for its versatility, strength, and ease of further processing into a wide range of industrial applications.

Steel Merchant Bars

Steel merchant bars are long steel products with simple cross-sections, such as round, square, flat, L-angle, T-shape and U-shape.

They are widely used in construction, fabrication, and manufacturing industries for making structural components, frameworks, and general steel products like gates, railings, and supports.

Light & Heavy Sections

Steel sections are structural elements used in construction and engineering for building frameworks, bridges, and other structures. They come in various shapes and sizes, each designed to carry specific types of loads. We can supply H-Beam, Equal and Unequal Angles, Channels, T-Sections, Rectangular Hollow Section (RHS) and Flat Bar.

Flat Products

Our expertise in handling the various types of Flat Steel products ensures our clients receive a cost effective and service driven solution.

Flat steel products, commonly known as steel sheet/coil and steel plate, come in various types including hot rolled coil (HRC), cold rolled coil (CRC), metallic coated steel, organic coated steel, coil plate, and reversing mill plate.

Steel Sheets/Coils are typically under 5mm in thickness, including hot rolled sheet, cold rolled sheet, metallic coated sheets, and organic coated sheets. HRC is made at high temperatures (~1700°F) and is less precise with a poorer surface finish compared to CRC.

Flat Steel Hot Rolled Coil is used directly or further processed into Cold Rolled Coil. Cold Rolled Coil - Made from batch or continuous annealing, with enhanced mechanical properties and surface finish, used in construction and automotive, and can be made into coated steel. Coated Steel includes hot dip-galvanized (HDG) steel, coated with zinc for corrosion resistance, and organic coated steel, also known as color-coated steel or pre-painted galvanized iron (PPGI).

Main Trading Categories

Steel Hot Rolled Coils & Sheets

Steel hot rolled coil and sheet are widely used products in the steel industry, known for their versatility and broad application range.

Hot Rolled Coil is a flat steel product that is produced by rolling steel at high temperatures, typically above 927°C which is above the steel's recrystallisation temperature. The high temperature allows the steel to be easily shaped and formed, resulting in a product with a rougher surface finish and less precise dimensions compared to cold-rolled steel.

HRC is commonly used in construction, automotive manufacturing, and heavy machinery, where precise dimensions are less critical, and the material's strength and durability are key.

Steel Cold Rolled Coils & Sheets

Cold rolled steel coils are steel products that have been processed through a rolling mill at room temperature, significantly below the steel’s recrystallization temperature. This process increases the steel's strength, hardness, and surface finish while providing more precise dimensions and a smoother surface compared to hot rolled steel.

Cold rolled steel coils are commonly used in applications requiring tight tolerances and superior surface quality, such as in the manufacturing of appliances, automotive parts, and metal furniture.

They are also often used as a base material for further processing, such as galvanizing or painting.

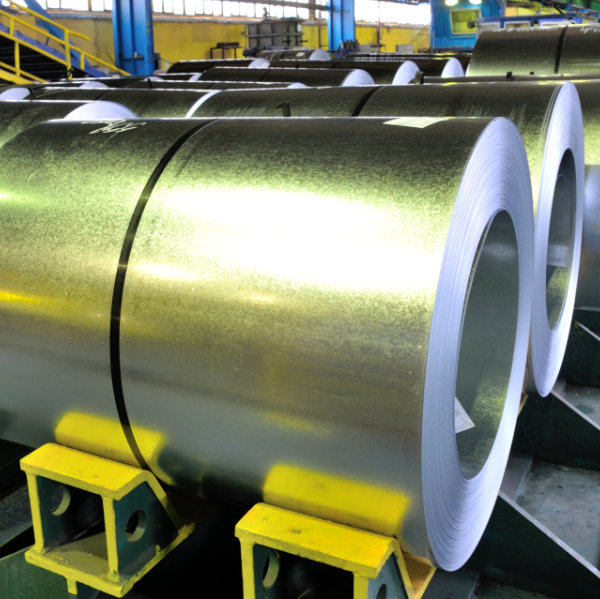

Steel Galvanized Coils & Sheets

Galvanised coils are a type of steel coil that has been coated with a layer of zinc to protect it from corrosion and rust. Galvanized coils are commonly used in construction, automotive manufacturing, and appliance production due to their strength, corrosion resistance, and ease of maintenance. They are available in various thicknesses and widths and can be further processed into sheets or other forms depending on the application.

Steel Pre Painted Coils

Prepainted steel coils are steel coils that have been coated with a layer of paint or other finishes before being used in manufacturing. This process involves applying paint to the steel surface, typically over a galvanized or other protective coating, to enhance durability, aesthetics, and corrosion resistance. Prepainted steel coils are widely used in industries like construction (for roofing, siding, and cladding), automotive, and appliance manufacturing. They come in various colours and finishes.

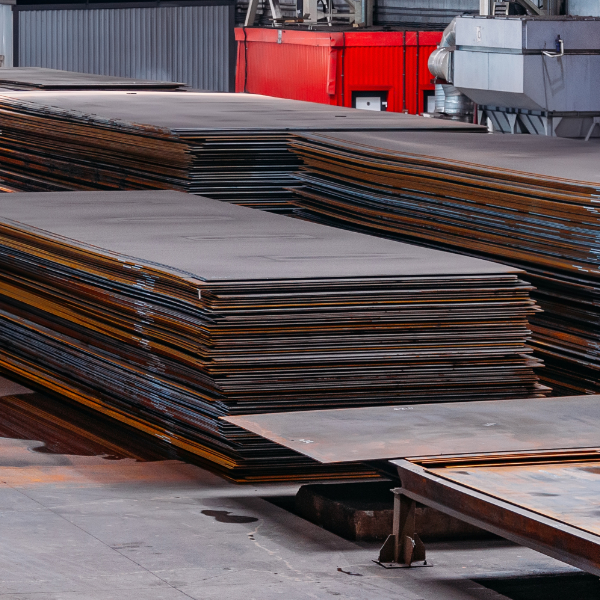

Heavy Plates

Steel reversing mill plate is a type of steel plate produced in a reversing mill, a rolling mill where the steel slab passes back and forth between rollers to gradually reduce its thickness. This process allows for the production of plates with precise thickness and flatness, making it suitable for heavy-duty applications. Reversing mill plates are typically thicker and wider than those produced by continuous rolling mills, and they are often used in construction, shipbuilding, heavy machinery, and pressure vessels.